OEM of probiotics product

Do you have any of the following problems?

Wanted to make probiotics product but was rejected by other companies…

Do not know anything about the risks of probiotics product…

Although want to commission production, but always worried about hygiene problems…

Do not know anything about the risks of probiotics product…

Although want to commission production, but always worried about hygiene problems…

The thing our company can do

Various risks are involved in the production and management of probiotics product.

With very few factories able to accept customer requests, we still actively accept many companies' requests for packaging and processing of probiotics product.

We believe that there are "values and happiness for our customers" in "things that other companies do not want to do".

We have carried out thorough sanitary management and equipment maintenance, continuously improved our services, and created an environment where our customers can consult us with confidence.

With very few factories able to accept customer requests, we still actively accept many companies' requests for packaging and processing of probiotics product.

We believe that there are "values and happiness for our customers" in "things that other companies do not want to do".

We have carried out thorough sanitary management and equipment maintenance, continuously improved our services, and created an environment where our customers can consult us with confidence.

Three reasons to choose

our company's probiotics product OEM

Zero risk of bacterial contamination for customers

~One of the few factories that can manufacture probiotics product~

~One of the few factories that can manufacture probiotics product~

The current situation is that few factories can handle bacterial contamination and other risks. And our company will not refuse to fill and package probiotics products like other factories, we take the risk in order to be able to give our customers more choices.

Thorough and complete hygiene management

~Production lines kept in high awareness~

~Production lines kept in high awareness~

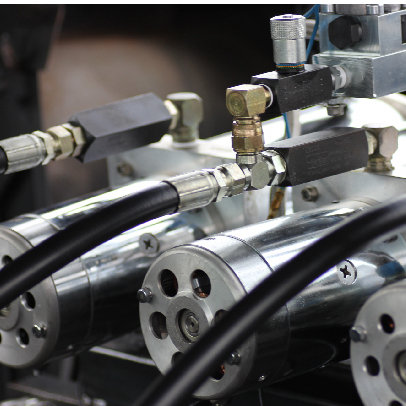

We maintain a safe and secure production line through the high hygiene awareness of each person on site and thorough hygiene management. In addition, we operate the factory in a way that reduces the possibility of contamination by separating the filling machine from the packaging room.

Well-equipped filling machinery and equipment

~Safe packaging of probiotics product~

~Safe packaging of probiotics product~

We have a full line of machines that enable the filling of live bacteria such as lactic acid bacteria and yeast, etc. We have a well-equipped environment that can safely perform various other types of processing and packaging, such as 3-way seal filling, stick filling, etc.

Factory facility & Environment

to prevent risk of bacterial contamination

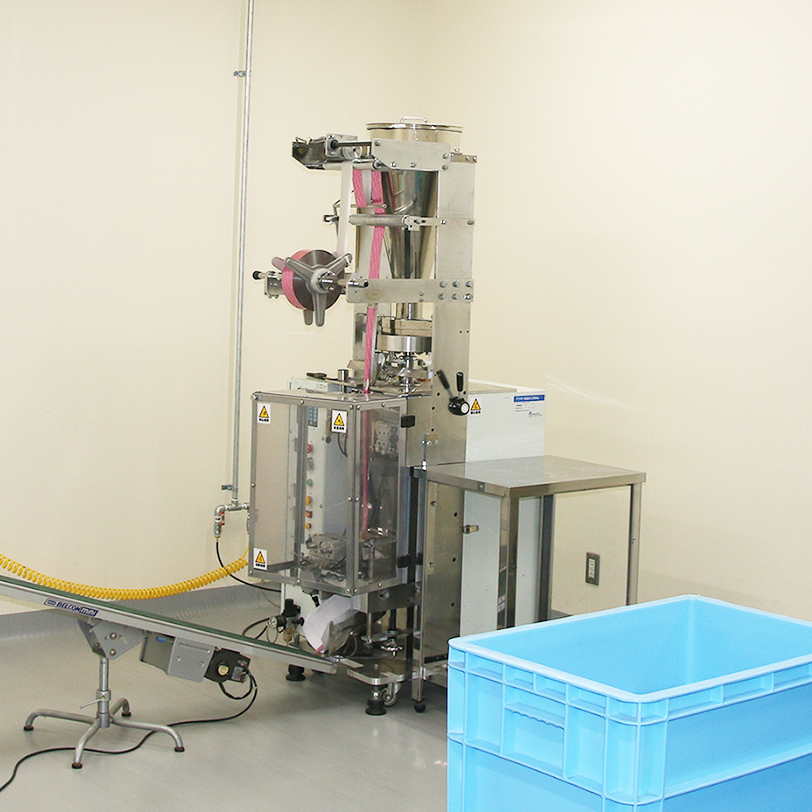

<One stick filling machine>

- Mass lightweight type: Powder and granule filling

- Finished width: 15,20,25,30mm

- Pitch: 30 to 130mm

- Capacity: 25-50 packages/minute

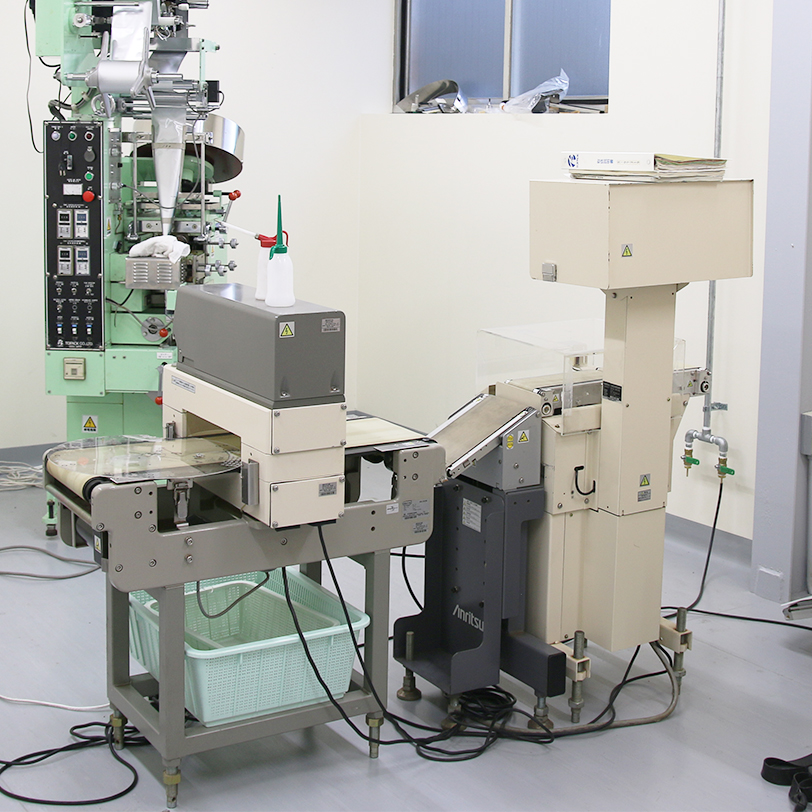

<One 3-way seal filling machine>

- Mass lightweight type: powder and granule filling

- Finished width: 40,50,55,60,70,80mm

- Pitch: 30 to 130mm

- LOT printable

- Capacity: 20 to 40 packages/minute

<One 3-way seal filling machine>

- Mass lightweight type: powder and granule filling

- Finished width (for powder): 40,45,50,55,60,70,80mm

- Finished width (for tablets): 50,55,60,70mm

- Pitch: 30 to 130mm

- LOT printable

- Capacity: 20 to 40 packages/minute

Other equipment

- Metal detector … 1 unit

- Weight checker … 2 units

- Rocking mixer 100L type … 1 unit

- Sugar coating pan (used as mixer)

- Horizontal belt sealer … 1 unit

- Shrink tunnel - 1 unit

- Box and AL bag printing machine (inkjet) - 1 unit

About the flow from inquiry to delivery

-

①Market research and product designDetermine product specifications based on customer needs and product concept.

①Market research and product designDetermine product specifications based on customer needs and product concept. -

②Make a sampleWe procure raw materials that meet client needs and product concepts.

②Make a sampleWe procure raw materials that meet client needs and product concepts. -

③Manufacturing DecisionDiscuss the samples with the customer and decide to start manufacturing.

③Manufacturing DecisionDiscuss the samples with the customer and decide to start manufacturing. -

④ProductionProduction is carried out in a thoroughly hygienic environment and is also based on delivery dates and the number of units produced.

④ProductionProduction is carried out in a thoroughly hygienic environment and is also based on delivery dates and the number of units produced. -

⑤ShippingShipment will be made to the pre-designated delivery location in accordance with the delivery date.

⑤ShippingShipment will be made to the pre-designated delivery location in accordance with the delivery date.

Contact us

It doesn't matter how small the problem is.

Please contact us to find out more.

Please contact us to find out more.

〒577-0065 3-1-10 Takaidanaka Higashiosaka-shi Osaka-fu

TEL:06-6782-1001/FAX:06-6782-1002

TEL:06-6782-1001/FAX:06-6782-1002